目录

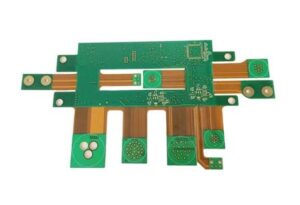

ToggleA hybrid solution that combines the features of stiff and flexible printed circuit boards (PCBs), rigid-flex circuit boards are used in the electronics industry. Engineers and manufacturers are increasingly drawn to this unique design because of its specific advantages that can be used in various applications.

Is Rigid-Flex a Good Thing?

Multiple layers of flexible and rigid substrates are integrated into rigid-flex circuit boards. This unique structure makes the ability to bend and flex complicated shapes without compromising structural integrity possible. The components are supported by the hard parts, and complex layouts and connections are made possible by the flexible areas.

Important Elements of Rigid Flex Circuit Boards

Space Efficiency: The capacity to keep space is a major benefit of rigid-flex designs, which is one of its main features. Electronic devices can have a smaller overall footprint when various functionalities are integrated into a single board. This works wonders in situations where space is at a premium.

Durability: Compared to standard printed circuit boards (PCBs), rigid-flex circuit boards tend to last longer. It is crucial for portable gadgets that are constantly on the go to have materials that are both durable and flexible.

Enhanced Performance: The shorter interconnections on these boards usually result in better electrical performance. When performance is critical, as it often is in high-frequency applications, this shorter cable can reduce signal loss and increase dependability.

Rigid-Flex Circuit Boards: Their Value and Use

The adaptability of rigid-flex circuit boards makes them useful in many different fields. A few significant examples include these:

Consumer Electronics: Devices like wearables, tablets, and smartphones benefit from rigid-flex boards because they allow for smaller designs without compromising functionality. One major benefit of these uses is how light they are.

Medical Devices: When space is at a premium and dependability is paramount, medical devices like imaging equipment and pacemakers rely on rigid-flex printed circuit boards (PCBs) to offer secure connections. Further enhancing their viability for medical applications is their capacity to tolerate extreme circumstances.

Defense and Aerospace: Rigid-flex circuit boards are perfect for use in aircraft because of their long lifespan and high performance. Important for mission-critical systems, they are capable of handling extreme conditions without losing operation.

Advantages of rigid-flex circuit boards

Design Flexibility: The design flexibility of rigid-flex boards enables the incorporation of more complex components into a single board, eliminating the need for several individual boards.

Reduced Assembly Costs: It is possible to reduce assembly costs by integrating many capabilities into a single board. Due to the reduced need for labor and materials, rigid-flex systems are more cost-effective.

Enhanced Reliability: The reduced number of solder joints and connections greatly reduces the likelihood of failure, leading to improved reliability. Device failure could have significant consequences in certain applications.

Opinions on Rigid-Flex Circuit Boards

Although rigid-flex circuit boards have obvious advantages, people have different views on how to put them into practice:

Views from Industry Experts: Because of their capacity to simplify design procedures and improve product reliability, rigid-flex printed circuit boards (PCBs) are widely supported by engineers for use in complicated applications.

Cost Considerations: Some producers are afraid of rigid-flex circuit boards because of the higher starting costs compared to more conventional solutions. Nevertheless, they frequently recognize that the savings from decreased assembly costs and increased reliability can exceed these early investments in the long run.

Conclusion

The combination of flexibility and durability offered by rigid-flex circuit boards is an enormous advancement in printed circuit board technology, and it’s exactly what today’s electronics need. Their space-saving and performance-enhancing capabilities make them an excellent option for many different types of companies. The usage of rigid-flex circuit boards is expected to grow in the future, propelling advancements in electronic design and production. Price and complexity are factors to think about, but the benefits they provide make them an important part of electronic device development going the future.

0