目录

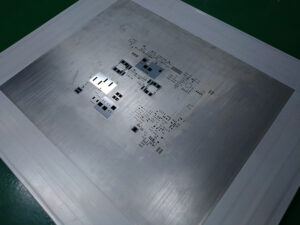

ToggleThanks to technological advancement, electronic manufacturers can now apply soldering paste with precision using SMT solder paste stencils. Circuit assembly can now be done without wasting time on prolonged point-to-point wiring. Solder paste is deposited on wiring boards through SMT stencils and the components are firmly placed.

Currently, there are different classifications of SMT solder paste stencils in the market. These stencils are classified based on ways of applying solder paste, their manufacturing methods, and what was used to manufacture them.

Classes of SMT Solder Paste Stencils Based on Ways of Applying Solder Paste

When stencils are classified based on how solder paste is applied, we have the following classes.

- Framed Stencils

These are the type of stencils with frames permanently fixed to their sides. These frames help to keep the stencils firmly in place with the right tension during usage. Its aperture walls are very smooth and its performance is optimized for flawless prints. Framed stencils are mainly used for bulk PCB production.

- Frameless Stencils

These stencils do not have permanently fixed frames and are mainly used for prototype runs. In comparison with the framed stencils, these stencils are very affordable. - Prototype Stencils

This type of SMT solder paste stencil is used for manual solder paste application. They are specially made with Gerber or CAD files to minimize errors during printing.

Classes of SMT Solder Paste Stencils Based on Methods Used in Manufacturing Them

In the factory, there are several ways of forming the aperture. With this in mind, we can classify stencils into the following classes;

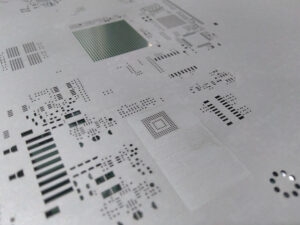

- Laser Cutting

During its manufacturing process, a laser machine is used to create its aperture. The use of laser ensures a very accurate and fine result which is why many people would readily go for this type of stencil. - Electroforming

This type is manufactured through an electroforming process using nickel. The process takes lots of time and its cost of production is pretty high compared to others. It is also called EFAB. - Chemical Etching

Using this method helps to reduce the cost of production. The aperture is formed from chemical etching. Even though this method does not produce the best quality stencils, they are still usable and very affordable.

Classes of SMT Solder Paste Stencils Based on the Materials Used to Manufacture Them

Stencils are made in a way that they can withstand tension in a work environment. This is why SMT stencils are made with durable materials to ensure a long-lasting quality. Based on the durable materials used, we have the following classes;

- Stainless Steel SMT Stencils

Just as the name implies, they are made with stainless steel and are mainly used for prototyping. They are still known as the best-quality stencils in the industry when compared to those manufactured with other materials. In prototyping, they help users to minimize errors. - Mylar and Kapton SMT Stencils

This class of Stencils is also used in prototyping to minimize errors and ensure an excellent result. They are made with Kapton materials and laser etching Mylar. They are more affordable than those made with stainless steel.

Conclusion

In choosing the best quality SMT solder paste stencil for your work, you need to consider the quality, usage, and budget. You can go over the description of the different SMT solder paste stencils above to find just the right one for your work. Lastly, only get your stencil from a trusted manufacturer or distributor to avoid getting cajoled into buying the wrong one for your work.

0