目录

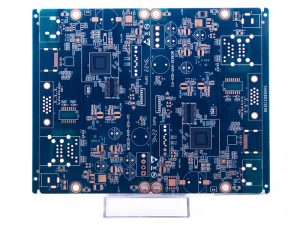

ToggleRecent years have seen a tremendous shift in aerospace technology, mostly due to improvements in printed circuit board (PCB) design and production. The advancements in communication, navigation, and control made possible by printed circuit boards (PCBs) have made them indispensable to contemporary aerospace systems. The significance of printed circuit boards (PCBs) in the aerospace industry is huge, especially given the sector’s penchant for innovation. The importance of PCB aerospace technology and its impact on the sector’s destiny are discussed in this article.

Developing PCB aerospace for use

Since the beginning, aerospace-printed circuit boards have undergone significant advancements. As the needs of the aircraft industry have grown, these components have progressed from simple circuit boards to intricate, multi-layered architectures. New materials and production methods have resulted in aeronautical PCBs that are more efficient, long-lasting, and dependable than before.

Why PCB Aerospace Are Beneficial

Due to their many useful features, PCB aerospace is an integral part of the aircraft industry. Among the many benefits, here are a few:

- Optimizing Space with a Lightweight Design: Lightweight and small in size, PCB aerospace makes the most of limited space in spacecraft and airplanes. Their efficient design and thin layers allow aerospace engineers to build vehicles with improved range and endurance, maximize payload capacity, and improve fuel efficiency.

- Transmission of Signals at Extreme Speeds: For efficient data transmission and system operation, PCB aerospace is essential. To provide low-loss and distortion-free signal transmission, they include regulated impedance and optimized trace routing. Radar systems, satellite communication, and flight control are just a few of the critical functions made possible by these specialized printed circuit boards (PCBs) that allow for the integration of contemporary communication systems, data links, and electronics.

- Adaptability in Extreme Environments: Extreme heights, temperature swings, humidity, and vibrations are just a few of the challenging environments in which aerospace equipment must function. To endure these difficult circumstances, PCB aerospace is custom-made. They are more resistant to mechanical stresses, moisture, and temperature fluctuations because of the unique materials and coatings used in their construction. The reduced likelihood of failures endangering safety is a direct result of this durability, which guarantees reliable operation in aeronautical environments.

- Reliability and System Integration: Electronic components used in aircraft applications, including microprocessors, sensors, actuators, and communication systems, are integrated on printed circuit boards (PCBs). Their job is to improve the system’s performance by facilitating communication and coordination across its many subsystems. Rigid testing procedures, innovative production methods, and stringent quality requirements guarantee the dependability of PCB aerospace. Important systems in aircraft applications rely on this reliability to keep running smoothly.

PCB Aerospace Applications

Spacecraft, military planes, and unmanned aerial vehicles are just a few of the many uses for PCB aerospace. To guarantee dependable communication, navigation, and control, these components are crucial to the operation of electronic systems in aeronautical vehicles.

Modern PCB Aerospace Developments

pcb aerospace technology is a dynamic area that experiences frequent advancements and new developments. Aerospace PCB manufacturers are at the forefront of electrical design innovation, offering a wide range of products including high-speed and rigid-flex boards, as well as flexible and rigid-flex printed circuit boards. These developments are influencing the development of aerospace technology and the industry’s future.

Dependability and Accuracy in Engineering

The aircraft industry relies heavily on precision engineering while assembling printed circuit boards (PCBs). Electronic parts used in aircraft must be able to withstand extreme temperatures, radiation, and the strong vibrations experienced by the system during takeoff and flight. To ensure that the circuitry functions correctly under these rigorous conditions, the aircraft sector requires PCB assembly with complex designs and meticulous soldering. The dependability of aircraft systems relies heavily on redundancy, which is designed using PCB assembly as a critical component.

Conclusion

Finally, printed circuit boards (PCBs) have allowed improvements in control systems, navigation, and communication, and have therefore become an essential component of aeronautical technology. The significance of printed circuit boards (PCBs) in the aerospace industry is only going to increase as the industry keeps pushing the limits of innovation. Aerospace printed circuit boards (PCBs) are well-positioned to influence the industry’s trajectory because of their dependability, precision engineering, and resistance to extreme conditions. It is becoming more apparent that the aerospace industry’s future success will depend on the ongoing improvement and development of PCB technology.

0